Silage Harvest Timing: Be Ready

August 27, 2020 | Category: Agronomy |

The 2020 corn crop is significantly ahead of last year regarding maturity. Producers who are looking to harvest silage will need to be prepared to chop much earlier than last year. Quick estimates would put a May 5, 2020, planting date to be harvested for silage around September 10–15 this fall. If your corn tasseled on July 26, 2020, then it will be at half-milk line approximately 42–47 days later. Obviously there are a lot of variables around environment and corn hybrids that will affect maturity. But I would expect the main silage harvest window to be September 7–20, so it will be important to get out in your fields the first of September to evaluate the maturity to catch it at the right moisture.

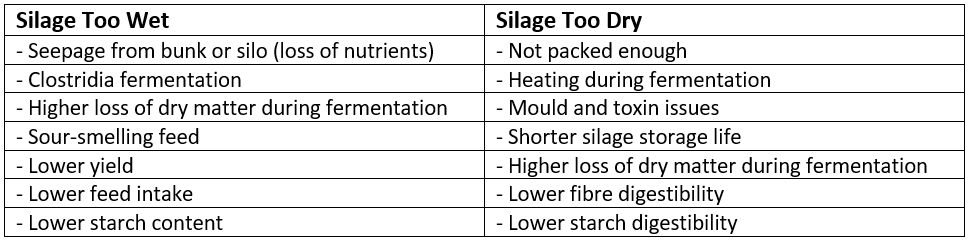

Also, dry-down curves in September will be much faster than we saw last year in October. Early September will be warmer and have longer days than October, allowing a more rapid dry-down. In the past, we have seen hot, dry days in early September take whole plant moisture content down by over 1% per day. So it will be very important for you to track the maturity and moisture content of your silage as it will change rapidly. The most important part of silage harvest is getting the crop in the silo, bag, or bunker at the correct moisture content!

Determining the Correct Silage Moisture for Your Farm

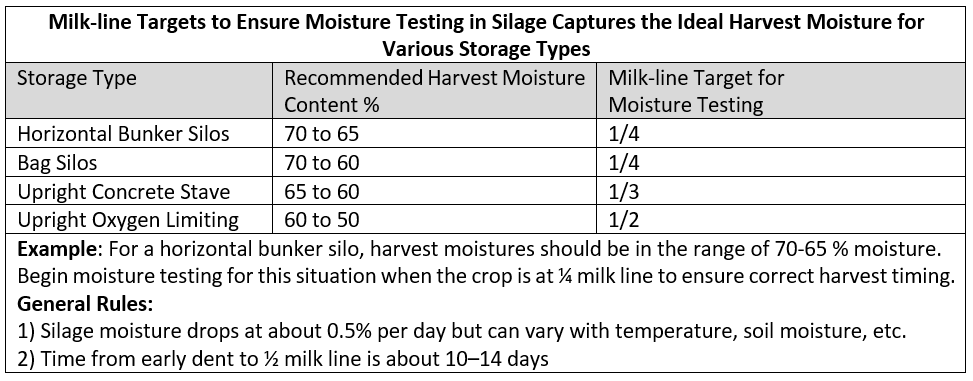

The type of storage that you use is the main factor that will determine the ideal moisture content at which to harvest your corn. Since you already have your storage in place, it is easy to match the ideal moisture content to your storage type. The principle on proper silage storage is to pack the silage tight enough to remove as much of the oxygen as possible out of the silage. This helps reduce the amount of aerobic bacterial growth in the silage, which causes dry matter loss and bunk shrink. We want the silage to begin anaerobic fermentation as quickly as possible. Higher moisture silage will pack tighter; however, too much moisture can cause seepage from the silo. The taller the silo, the larger the bunker pit and heavier the packing tractor will allow you to move to the lower end of these moisture ranges, as the weight of the silage will help compact and displace air pockets. See the chart below to determine your ideal silage moisture content and some guidelines for moisture testing and dry-down.

How to Determine Moisture Content of Your Standing Corn Silage

Milk-line Estimate

The milk line is a physical line that marks the separation between solid starch and milky starch. It progresses from the top of the kernel at early dent down to the tip of the kernel where it will eventually black layer at maturity. This is a guideline that helps producers estimate whole plant moisture while in the field. There will be some variation on accuracy depending on weather and the individual hybrids. Note that ½ milk line is approximately 65% moisture. This should only be used as a guideline. Actual sampling to determine moisture content is much more precise.

Chipper Test

This is a great way to get an accurate sample of your whole plant moisture. Take 6–12 representative stalks of corn from your silage field and process them through a wood chipper or silage harvester. Collect the sample and mix thoroughly so that the sample contains a homogenous blend of cob, leaf, and stalk. Use a Koster tester, microwave, or accredited lab to determine the moisture content of the silage. These need to be done prior to harvesting (see milk-line targets above) to give an estimate of how long to wait until the corn has reached a desired moisture. For example, if the sample came back at 68%, but the producer wants their silage to be 65%, then approximately six days from the sample being taken, the corn will reach the desired moisture content (0.5% moisture loss per day on average).

Physical Appearance of the Corn Plants

Generally, the visual appearance of the corn plants can provide some indication of the moisture content. However, this is very subjective to each individual and varies from year to year. There are many different factors such as hybrid characteristics, leaf diseases, fertility, and environment that can alter the appearance of the corn plants. Modern hybrids also have better “stay green” traits that make them appear ‘wetter’ in the fall than they may actually be. The improved stay green will allow the plant to stay alive longer while starch accumulates in the kernels and the cob moisture content decreases.

Factors Affecting Dry-down in Corn Silage

Silage-specific hybrids are selected and bred for corn-silage production. Generally, these hybrids will have a slower dry-down curve to allow for a wider harvest window in the fall. This is generally due to kernel texture and the husk on the cob, and some of these hybrids will have a longer and/or tighter husk, which slows down the grain content dry-down.

Dual-purpose type hybrids are generally grain-corn hybrids that have suitable characteristics for silage production. Because these hybrids are generally selected primarily for grain production, fast dry-down is often sought after. For silage, this can narrow the ideal harvest window, which can prove challenging to target the correct harvest date. Producers using dual-purpose-type varieties need to be very diligent to catch the rapid dry-down curves of their hybrids at the right point.

Hybrid Maturity for Your Area

The dry-down of a corn plant is a physiological process. Today we have hybrids that range from 1950 CHU to 3300 CHU. It is important to know the maturity of your hybrids and how they will adapt to your area. Matching up maturity with planting date, maturity zone, and expected harvest date will all help you target the ideal moisture for harvesting your silage. Generally, the recommendation is to grow a silage variety that is 150–200 CHU longer than adapted grain corn for the area. If your silage hybrid tends to be close to adapted grain hybrids, you should expect to harvest early in the season. If you have an ultra-long maturity hybrid, you would expect to be toward the end of the season for harvesting.

Fungicides on Corn Silage

When fungicides have been applied to corn-silage fields, this needs to be considered when evaluating harvest date. Fungicides will tend to keep the corn plants healthier and alive longer, essentially delaying their maturity and dry-down. Side-by-side comp

arisons of corn treated with fungicides and without will show that the treated corn will be approximately 3% wetter on average. During some harvest periods, this may add a week delay in harvest to get to the ideal moisture content.

Weather

As farmers, we are always at the mercy of the weather. The weather that we encounter each harvest season will greatly affect how fast your silage dries down. Hot, dry weather can greatly accelerate the dry-down to over 1% loss per day. And cool, wet weather can virtually stall dry-down. On average, we tend to say that corn silage will drop 0.5% moisture per day or 3–4% per week.

Why It is Important to Have the Right Moisture Content

Conclusion

It is critical for you to know your ideal moisture content for your corn silage—and even more important for you to harvest at the correct moisture. As outlined above, there are a number of ways to determine the moisture content of your corn silage, of which a physical test is most accurate. Patience and attention to detail at harvest time will pay dividends for you for the entire next year.

Sources

http://corn.agronomy.wisc.edu/AA/A023.aspx

http://www.omafra.gov.on.ca/english/crops/facts/frost_silage.htm

http://www.omafra.gov.on.ca/english/crops/facts/13-051.htm

http://fieldcropnews.com/2012/08/harvesting-corn-silage-at-the-right-moisture/