Gaining that EXTRA bushel! – Winter Management

March 11, 2019 | Category: Agronomy |As I sit in my office; looking out the window at the thermometer reading negative 15°C, the sun is shining on me with its intense heat. Days are getting longer, and spring is around the corner. Now is the time we should be increasing our monitoring of stored grain. Specialist suggest routinely monitoring our stored grain more frequently (preferably every 2 weeks or less) as we approach milder temperatures.

After a stressful 2018 harvest period, corn that may not have been dried to sufficient moisture (under 15%) or poor-quality grain such as lower test weight, immature kernels, high percentage of fines, or the presence of mould have higher risk of spoilage thus storage bin should be checked more often.

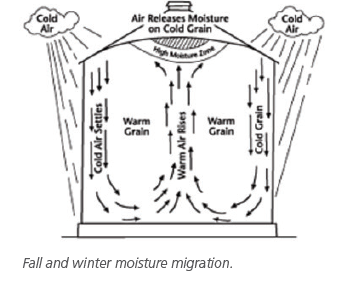

As the temperature drops when we enter winter months we often pay less attention to our stored commodities, thinking that our grain is safer. Fluctuating weather and grain respiration can result in condensation forming. Condensation, which typically occurs on the surface of the grain can accelerate mould growth and fermentation leading to grain spoilage and mycotoxin development. Grain crusting, sprouting, and mold are often visible on the top surface of the grain, which is mostly a result of headspace condensation. (Figure 1)

Monitoring Check list:

Although, technologies in the grain storage can help monitor grain at the touch of a button, we still need to keep the human element involved.

– Check the visual appearance of grain; Corn should not look dusty or dull or having crusting or soggy surface on top of the grain. Sprouting and mould may also be visually present.

-Look for moisture or condensation on the underside of bin roof. Moisture marks air movement in the bin.

-Smell the grain for indications of mouldy or musty corn. If odours present take immediate action as fermentation indications severe problems.

-Start fans – if the grain feels humid, or grain temperature feels warmer than it should.

-Actively take and record temperature of the grain; if temperatures begin to increase noticeably, a hot spot may be occurring. (Temperature rise of 2 to 5°C per week and/or moisture increase of over 0.5% are strong indicators).

When to Aerate:

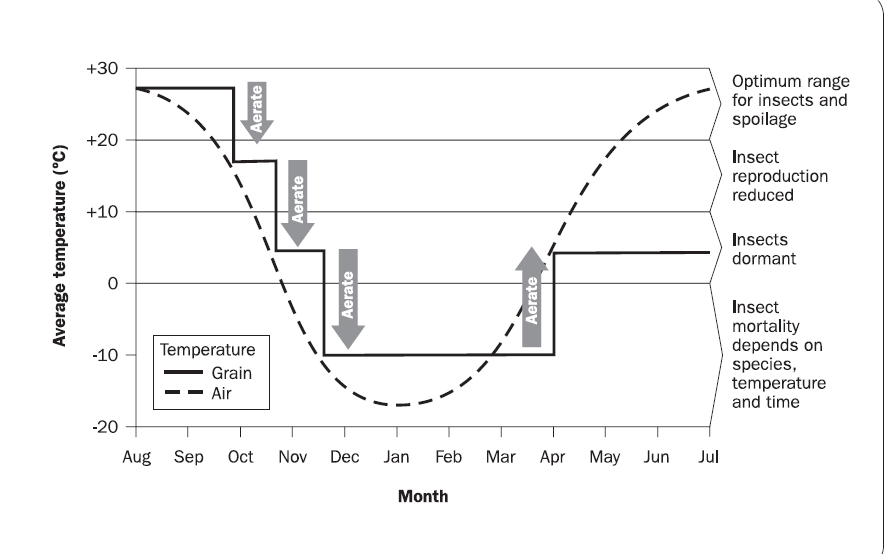

As spring temperatures begin to rise, aeration is important to grain storage as bin surfaces are warmed by sun and air outside. Warming the grain is necessary if extended storage is required. It is recommended to start aeration as soon as average outside temperature is 5°C to 7°C higher than the grain temperature. Remember that insect activity increases with grain temperatures above 17°C. OMAFRA suggests to maintain bin temperatures close to the average nighttime temperatures during warm months. (See Figure 2)

Figure 2

STAY SAFE

Always follow the farm and bin safety protocols when entering a bin to avoid grain entrapment. Such protocols include electrical lockout- never enter a bin when unloading equipment is running.

Wear the proper safety harness with suitable ropes, NEVER work alone; always practice a buddy system.

Never trust a crust! Use a long pole from outside the bid to test the grain surfaces, or dislodge steep piles.

Respirators or a dust mask is a must.

Sources:

1 Dyck J, Spieser H. 2015. Grain Aeration. OMAFRA Factsheet 15-039. www.omafra.gov.on.ca/english/engineer/facts/15-039.pdf

2 Quinn R. 2014.Checking Stored grain Key in Winter.http://agfax.com/2014/01/07/checking-stored-grain-key-winter/.

3 Dorn T. 2012.Mid Winter to Spring Grain Storage Management.. University of Nebraska-Lincoln.Http://cropwatch.unl.edu/mid-winter-spring-grain-storage-management

4. OMAFRA, 2018. Storage tips for Mouldy Corn. Available fieldcropnews.com/2018/storage-tips-for-mouldy-corn/